Molding and Casting

What I learnt

In this class, I learnt how to make a mold and cast my design out. First, I had to make a design out in Fusion360.

Then, I had to go to the manufacture tab in Fusion 360 and make the gcode for the design. Then I milled out the design on styrofoam and the milled product is shown below.

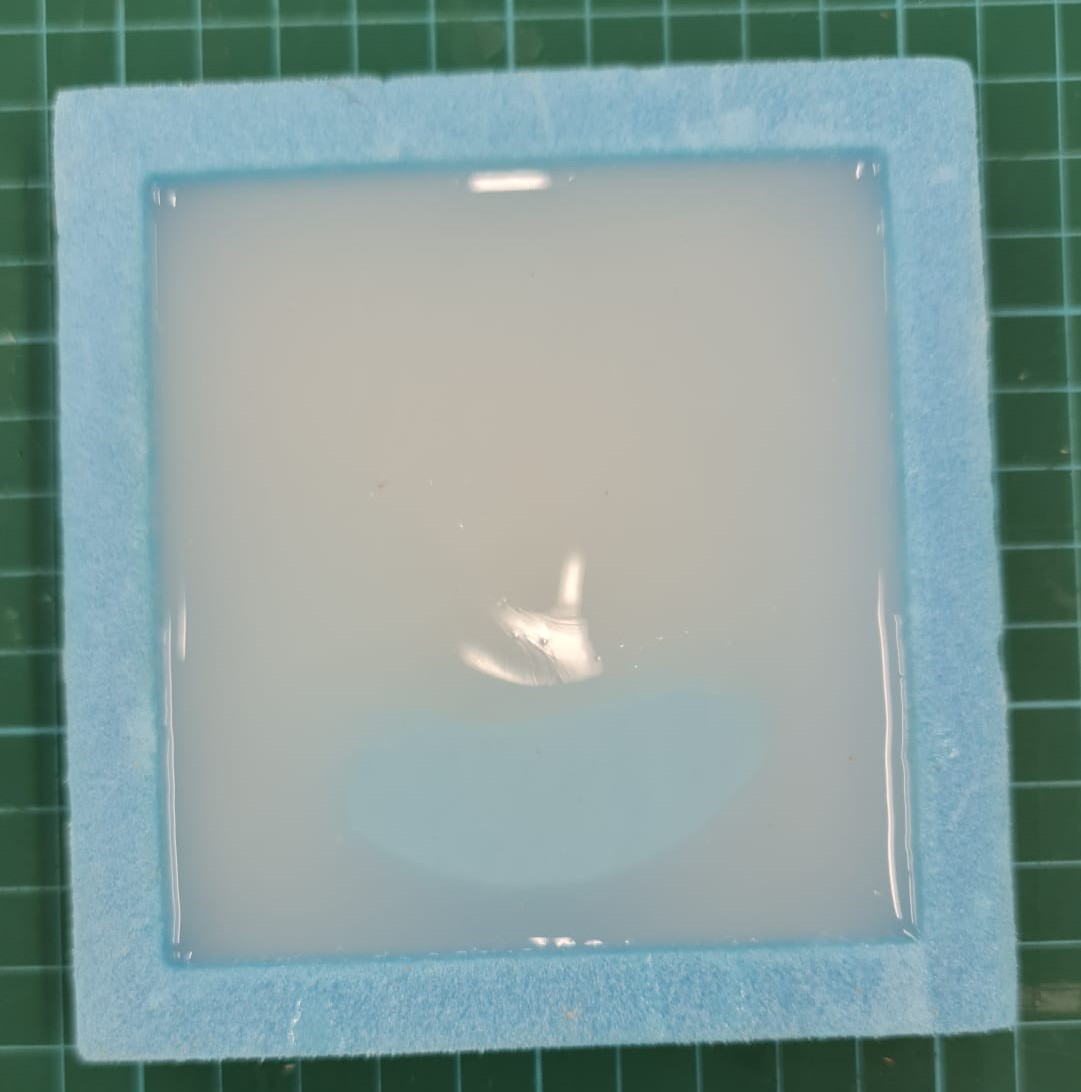

I then had to mix the silicon parts A and B to a 1:1 ratio and pour it into the mold. The silicon took around 24 hours to dry but the finished product is this.

I then removed the mold from the styrofoam and had to clean out the mold so that when I cast out my design, the cast would be more smooth and had less unwanted product stuck to the cast that I had to sand off later.

I then mixed up the plastic parts A and B with a 10:9 ratio and pour it into the mold. This time, I only had to wait about half an hour for the plastic to harden.

I then sanded the cast down and cleaned it. This is the finished product.